News

Building a boat – Skiff Story Part 2

‘If you can build a boat you can build anything!’

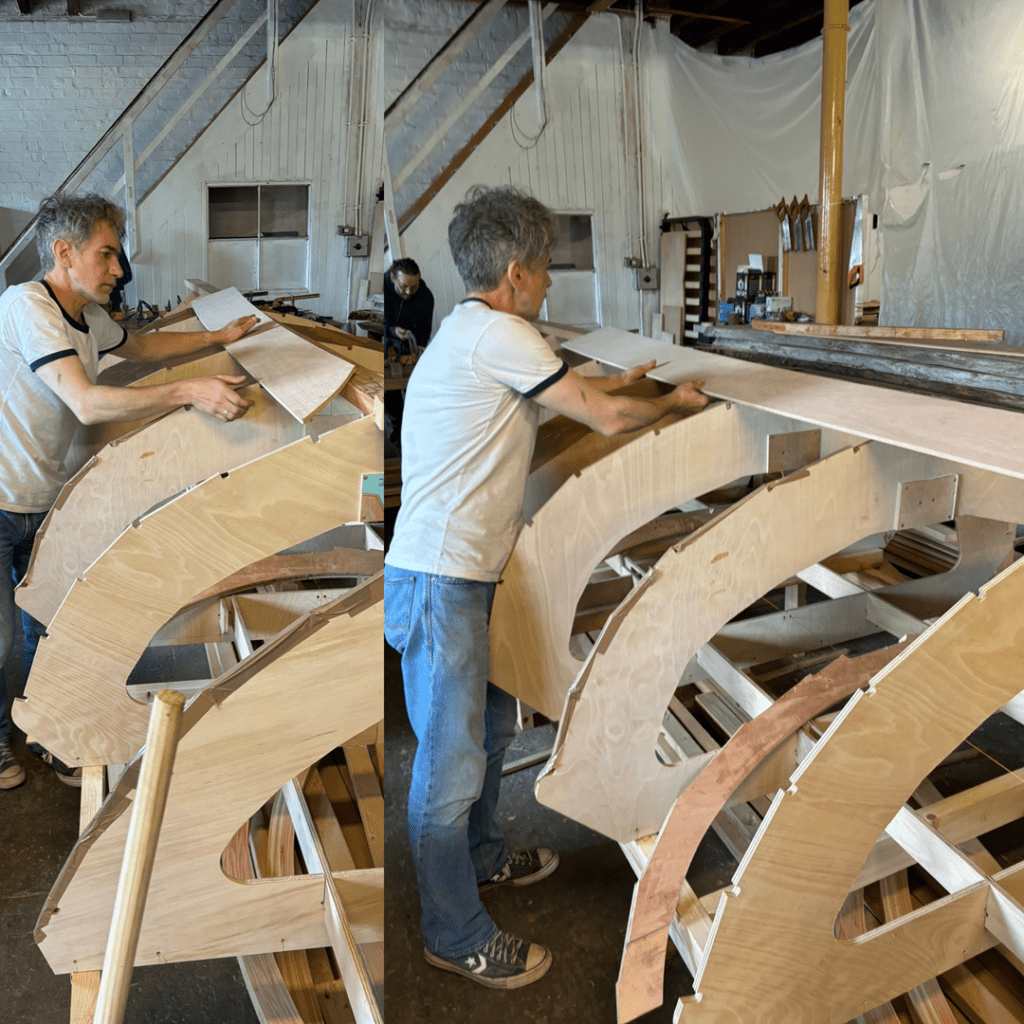

Inspired by what she’s seen so far, GCP’s volunteer storycatcher, Caroline, couldn’t resist another visit to the Granton warehouse to see our woodwork team in action and check the progress of our boat build.

Yes, we’re building a Scottish clinker-style rowing boat known as a St Ayles Skiff.

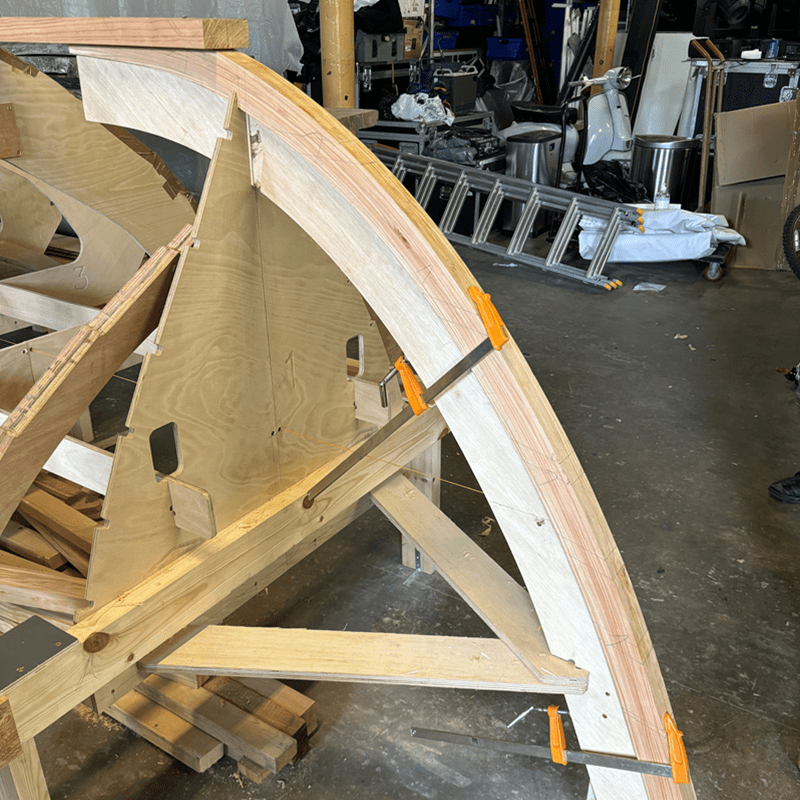

Tucked away in a workshop behind Granton Lighthouse, something magical is starting to happen. The skeleton of a rowing boat is already emerging.

Team members Aiden, Wojtek, Stephen and Frankie, led by expert boat builder, Campbell, are quietly working hard building a crucial element of the skiff, the stern apron… for the second time!

An update from the Skiff team

The bow apron was completed weeks ago and is set firmly in place. The stern apron should also have been completed but recent heavy rain and a leaky workshop roof have created setbacks for the team. Sadly, the rain damaged the first stern apron the team had painstakingly made.

GCP Member Stephen says,

‘Rainwater can get into the smallest crack and it caused the stern apron to split, so that’s not good enough, we have to make it again.’

Making a (second) stern apron

On the day of Caroline’s visit, she had the privilege of witnessing the team working together confidently, quickly and professionally, as they remade the crucial stern apron in a 5-stage process:

Stage one

Project Leader, Campbell, explains the team’s approach,

‘Preparation is always key. Aprons are made from laminated wood and the proxy resin (glue) used dries quickly, so it is crucial that all required materials and tools were there ready when needed’.

The team assembles the necessary elements including the resin itself, microfibres to create a thicker glue, vices to secure the wood and resin in place and, of course, the layers of plywood required to do the job. These all surround the frame that the wood would soon be shaped around.

Stage two

Campbell takes what looks like a hairdryer to warm the plywood. Opening the pores of the wood makes it more absorbent. The resin itself is also warmed, ideally the air temperature should be between 10 and 20 degrees centigrade to ensure the most effective application.

Stage three

This stage is known as ‘wetting the surface’ for good reason, as this is when things get very messy. Glue needs to be spread evenly across all surfaces of the wood and the team definitely need their gloves to do this. An initial coat of resin is used to cover the plywood followed by a second, thicker coat, containing the microfibres, which help fill in any gaps in the wood.

Stage four

This stage is so impressive! The laminated wood is now dripping with resin and ready to be shaped across the frame. At this point, everyone in the team comes together. They know their roles, what needs to be done and quietly help as Campbell ensures the wood is in place and clamped, before the resin starts to dry.

Stage five

Next, the clamping begins and the team aren’t satisfied until all 17 clamps are tightly attached to the wood to ensure there are no gaps. The newly-shaped apron is then left for the next week to set firmly before it can fully transform into an apron and be attached to the stern.

As you can see, the process is smooth, calm and effective. It really is fantastic teamwork…

Next steps

There will be exciting developments over the summer.

Look out for the two scale models of the skiff, a Members’ competition to choose the name of the boat, plus the design of the paint scheme and strip for GCP’s skiff row team!

Campbell is excited and delighted with the project,

‘The build is enabling us to do so much more than just make a skiff!’

Be part of GCP’s Skiff Story

Can you help support GCP’s Skiff project?

A BIG THANK YOU

Our key funders for this project are National Lottery Heritage Fund, HSBC, Edinburgh Airport and John Lewis & Partners. We thank them for their essential continued support.

How to support GCP

Please help us to keep providing support and opportunities to vulnerable people. There are various ways you can support our community. You can donate, fund or sponsor, support our social enterprises and volunteer.

Support our Social Enterprises

Wood Workshop >>

Tartan Shop >>

Event Hire Service >>

Visit Coffee Saints >>

AND follow, like and share on our Socials

A BIG THANK YOU

The Grassmarket Community Project’s Members Programme relies on the generosity of our customers, funders and donors. Our key funders for this area of our work are Nationwide Community Grants, The Robertson Trust and EVOC/Scottish Government Communities Mental Health and Wellbeing Fund. We thank them for their essential continued support.